- News and Events

- News

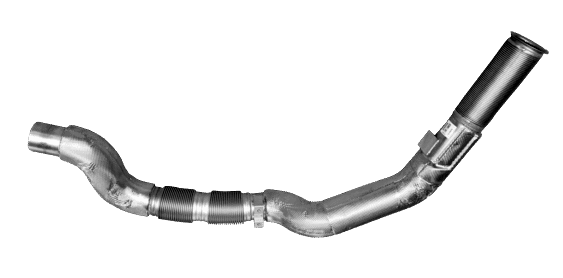

- It's Not Just a Pipe!

A modern exhaust aftertreatment solution is a complex system of technologies which in combination ensures that the exhaust gas is clean and in compliance with even the toughest emission regulations. Today the emission system is much more than technology in the silencer, catalysts and filters built into it. Without the proper technologies for the up-stream pipes that carries the exhaust gas from the engine, the whole system efficiency will be compromised.

This is why it is important to remember the critical role that pipes and insulation play along with all other emission technologies as part of an integrated system when designing solutions.

A Challenging Temperature Profile

At the end of 2017, Iveco were designing and introducing a new LNG Stralis model to the market. A LNG powertrain carries it’s fuel in form of Liquified Natural Gas, stored at -125°C in cryogenic tanks, and feeds it to the engines in gaseous form after being heated in a heat exchanger. The temperature of the exhaust gas after combustion can go up to 850°C which is highly unusual temperatures compared to conventional Diesel powertrains. This calls for the re-thinking of all parts that could be potentially exposed, from raw-materials, to decoupling elements, and insulation technologies.

Iveco involved Dinex Engineering team to find the solution to the problem of limiting the pipe’s outer (skin) temperature to a maximum of 200 C, both to protect auxiliary components, but also to keep as much heat inside the pipe as possible to boost the emission reduction efficiency. After several thermal tests and simulations, Dinex was able to find the right solution through a unique combination of different insulation layers which combined delivers the expected thermal properties within a competitive price level.

Shortcut to Greener and Cleaner Transport

The use of Natural Gas & Biogas as a fuel for medium and heavy duty commercial vehicles continues to grow in all regions of the world. The combination of very little NOx and Particulate emissions, and a 20-30% lower CO2 footprint (even above 90% with Bio-gas), not to mention a lower noise level, make Natural Gas vehicles a solid alternative for urban as well as long haul applications. Highly driven by the global environmental and cleanair agenda, bio-CNG and bio-LNG applications are facilitators of the transition towards a decarbonized future - a key objective in the building of a better world for future generations.

Iveco is one of the leading brands of Natural Gas powertrains, offering a wide range of application and models based on wellproven technology and with an undisputable TCO (Total Cost of Ownership) advantage for end-customers. In 2018, the 460 hp Iveco Stralis LNG demonstrated an impressive range of 1.728 km on a single re-fuelling – reaching a 40% fuel saving compared to Diesel.

Dinex is proud to contribute to a cleaner, greener and still affordable future, and supplies today several key technologies for modern exhaust aftertreatment solutions to customers all over the world. Besides the high-temperature capable front pipes for Iveco’s LNG Euro VI-E engines, Dinex also develops, produces and delivers annually over 10.000 Three-Way-Catalysts (TWC) used on natural and biogas fueled Euro VI vehicles to leading OEMs.

Do you want to learn more about Dinex’ capabilities within insulation technologies, catalysts, and full system integration of emission solutions for Natural Gas engines? Reach out to our team, and they will happily get back to you: